#COMMERCIAL ARCHITECTURE PROJECTS

Antifragile by carlo bailey proposes lightweight biotech factory of silk

Under the guidance of critic david benjamin, the brief of carlo bailey’s ‘antifragile’ project at columbia university’s GSAPP was to design a pilot factory for ecovative, a company that develops biomaterials from natural growth processes.

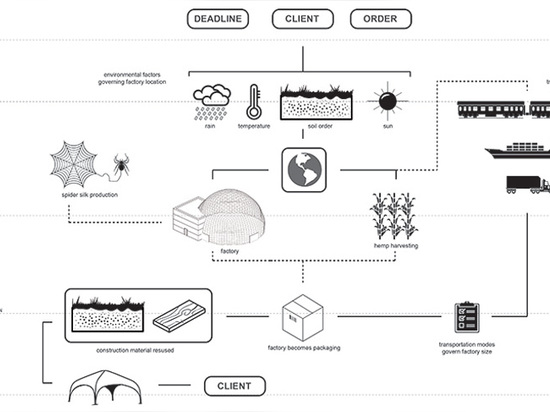

At three different scales, the project seeks to provide the framework for a circular economy within the brand’s business model and to hedge the risks associated with rising commodity prices and resource depletion: with the creation of a material sourcing and multi-modal distribution modelling interface, by developing an inflatable, lightweight and easy to assemble structure, and by harvesting living organisms (spiders) to produce the building fabric (silk).

the workshop is a mobile pay-per-use unit that follows regional agricultural production cycles to optimize the use of organic resources. the facility also doubles as the packaging container for client shipments and thus responds to constraints given by modes of transportation.

an algorithm is utilized to search locations throughout the globe to find an optimal site that satisfies ideal hemp cultivation parameters (as hemp is the main substrate used to produce ecovative’s goods). in addition, the formula also provides routes for distribution and energy use. more weight is placed on variables to mitigate against the inefficiencies that come about through the blind pursuit of local production. depending on the chosen mode of transportation, a particular module size is chosen.

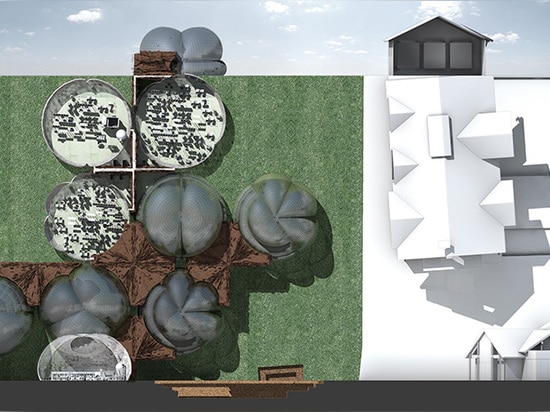

the next step before construction is the generation of the floor layout. the plan is developed by a calculation using binary strings to distribute the three program types, by keeping the growth areas towards the center in close proximity to the mould and customization space, and by keeping the display towards the periphery.

on-site construction is limited to three operations for ease of assembly, beginning with the hemp being harvested. once the program pod modules arrive, they are unpackaged, unfolded and inflated. local ground is then excavated to provide the material for the rammed earth office walls that surround the offices and desks. this system is enveloped by spider silk fabric that brings light inside through a manipulation of tension cables that focus the density of the strands at specific locations. as soon as the desired client product is manufactured, the disassembly commences, with the components returned to the ground, and the formwork and factory core to be reused for the next job. the silk material is deflated and becomes the packaging enabling the transportation of goods.